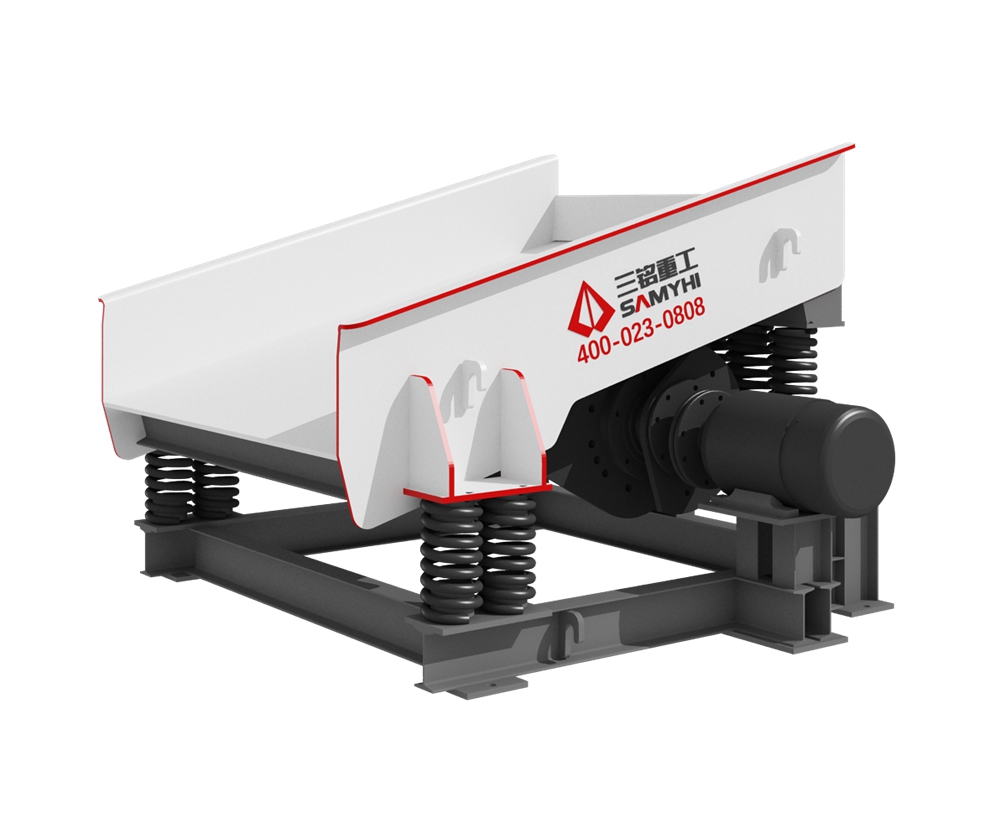

[Product Introduction] : a unique design of large capacity, dehydration sufficient dehydration equipment.

[Processing capacity] : ≤200t/h

[Application] : Longjian Group LZT dehydration screen is widely used in tailings dry drainage, concentrate dehydration, refining mud concentration, debris removal, carbon pulp separation and other filter dehydration equipment industry, especially suitable for the treatment of fine minerals.

- Introduction

- parameters

This series of products are mainly used for dehydration, desliming, desmediating, suitable for sand washing in sand and stone field, coal preparation plant slime recovery, tailings dry discharge in concentrators, soil remediation and sewage treatment, etc., with large capacity, high screening efficiency, low moisture content of finished materials, high cost-effective characteristics.

◎ High working frequency, high vibration intensity, low moisture on the screen, high unit processing capacity;

◎ Motor + bearing block + coupling combination as excitation source, strong power, reliable structure;

◎ Pre-dehydration sieve plate screen surface and level into 45 degrees installation, dehydration sieve plate negative inclination installation, increase the dehydration area and promote material dehydration as soon as possible to form a filter layer;

◎ Torsional shear high-strength bolts are used in the connection between the side plate and the beam, the motor base and the strengthening plate, and there is no weld, which avoids the side plate cracking caused by welding stress;

◎ The sieve plate is made of imported polyurethane material, with high porosity, good water permeability and long service life; ◎ Rubber spring, low noise, good vibration reduction effect; The side plate is made of low alloy structural steel, which has good weldability and high strength.

.png)